Introduction

SMARC is a cyber-physical system designed to introduce a systems-thinking approach to e-waste recycling. Specifically, the SMARC system has been designed to intervene at the point of e-waste collection, to in-turn support the downstream challenges in processing and recycling e-waste.

To demonstrate how SMARC assists with optimising processes across the e-waste recycling system, you can explore three different perspectives to the SMARC system.

- User Story

- Co-Regulatory Arrangement Story

- Manufacturer Story

User Story

SMARC has a variety of specific users. In this regard, it is truly cybernetic system that works across boundaries and actors to unify a system that is currently fractured. The prototype unit we have here is built for our domestic market. So households, apartments, units. The design of the unit is such that it can be easily scaled for other settings, including businesses and community spaces. To demonstrate the user experience, we have the three phones which representing three different types of ways we propose for e-waste to be processed.

- Ewtto (recycle)

- Sony Ericsson Xperia (repurpose)

- Apple iPhone 5C (resell).

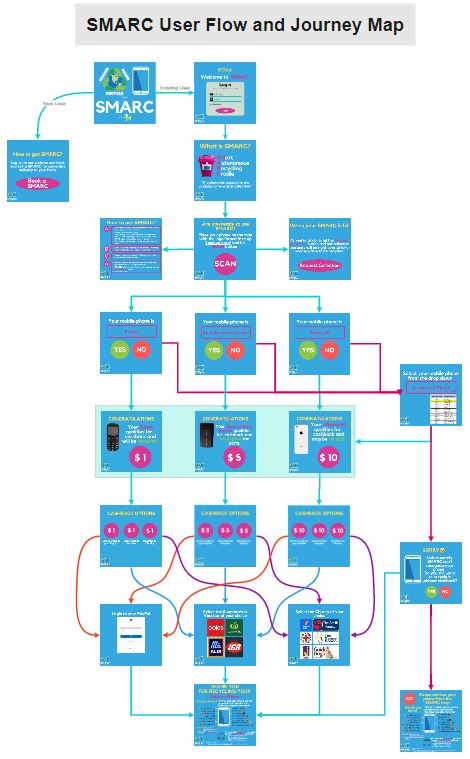

- If you want it recycled and out of your house, you need to set up a SMARC account and order delivery of a SMARC unit to your house [DISPLAY THE SMARC ORDER PAGE].

- This is a very simple process using our SMARC app.

- Our delivery and collection partners, like Woolworths, Coles and Auspost, will deliver a SMARC to your home within 24 hours of your request.

- Once SMARC arrives, you can access the app again directly via the SMARC unit.

- You can toggle through the introductory information, including a UX guide to ensure intuitive use of SMARC [DISPLAY THE SMARC UX PAGE]. The guide steps you through easy steps to use SMARC, following these letter labels across the unit.

- The camera takes an image of the phone and runs it through the ML model, which identifies the make and model of the device.

- The ML model is trained according to data provided by manufacturers of the device.

- For this to function as intended, it would require an expansion of the existing regulations to require technology manufacturers and importers to provide image data of any item they are manufacturing in Australia.

- In addition to identifying the device, the ML model assesses its remaining utility as per example below:

- Ewtto is assessed as having no remaining utility. Accordingly, it is assessed as being suitable only for recycling. The cashback offer for the Ewtto is limited to $1.

- Sony Ericsson Xperia is assessed as having a lot of componentry that could be recovered and reused. Given the potential for some components to be repurposed, the cashback offer is $5.

- Apple iPhone 5C is relatively new and is assessed as being a device for which there is existing demand. Accordingly, the ML system determines that it could be resold in its entirety. Given the resale potential, the cashback offer is $10.

- As you finish up with the machine, it provides you with a breakdown of the kinds of resources that can be recovered from mobile phones. At scale, we’d like this aspect to be specific to the device being recycled – this is likely going to require cooperation from device manufacturers and the introduction of additional regulations.

- Notably, there are already obligations imposed on producers and importers of certain technological products into Australia – namely computers and televisions. SMARC highlights the need to expand these obligations to mobile phones and all products that become e-waste. While a CPS like SMARC could make a significant contribution to the entire e-waste system by targeting the stage of collection, ultimately there is also a need for regulatory reform to support this system. We’d be happy to talk about this further also.

- When you’re finished with SMARC and want it collected, just click the ‘Request Collection’, to notify our delivery partners that it is ready to go.

In this example we have only demonstrated the RECYCLE/REPURPOSE/RESELL function. However, SMARC also facilitates e-waste to be RECYCLED and/or REPURPOSED and/or RESELL. We designed SMARC to include these three functions because we recognised that recycling e-waste is not always the solution. Recycling requires energy in its own right and can be completely unnecessary where the item is either still functional or contains components that are still functional. We wanted to bring these different means of dealing with e-waste together.

Co-Regulatory Arrangement Story

Co-Regulatory Arrangements are organisations set up by manufacturers and importers of tech into Australia to satisfy the requirements of the legislation which governs e-waste recycling in Australia – Recycling and Waste Reduction act 2020. The Act requires manufacturers and importers of specific times of technology, namely TVs, computers and computer peripherals – to ensure there are mechanisms in place for the recycling of these products. They do this by banding together and funding these co-regulatory arrangements.

In the course of researching this prototype, we spoke with co-regulatory arrangements who informed us that one of their biggest challenges is with the collection of e-waste. Currently, this occurs via disparate collection points across businesses and suburbs, where people can take their e-waste to be deposited – limited by law to TVs and computer peripherals. This results in low volumes of e-waste, low quality of e-waste (contaminated by other things) and uneconomic collection processes because they need to arrange collection even when they are not sure how much is there or what the quality is.

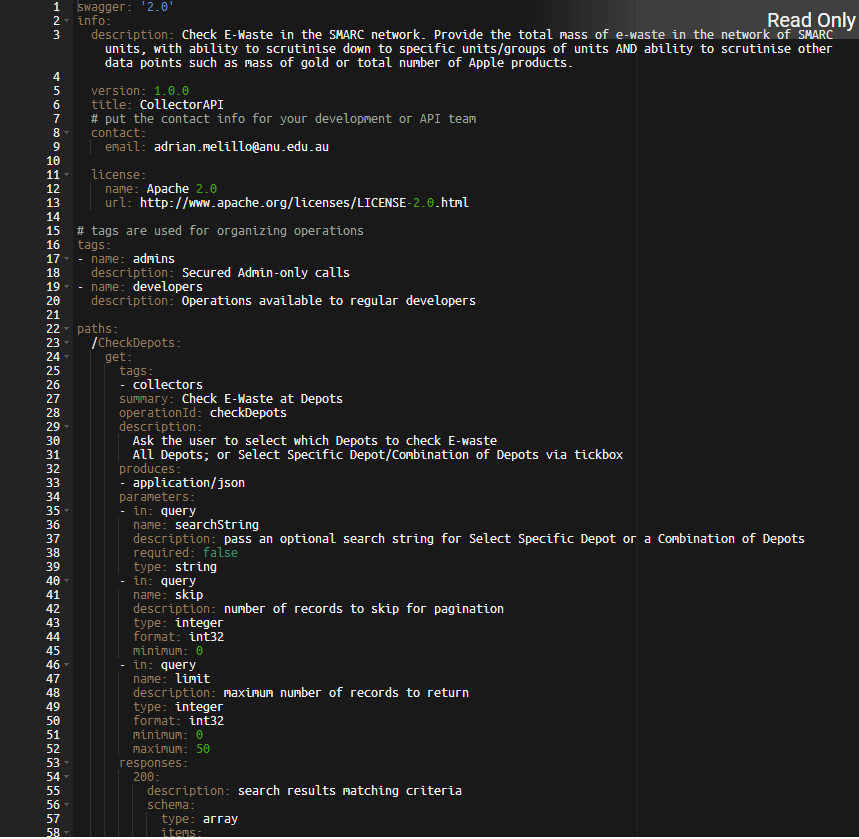

SMARC seeks to directly address the problems encountered by Co-Regulatory Arrangements by giving them live data across the entirety of the e-waste collection system. The Co-Regulatory Arrangements can access this data by way of the purpose built SMARC collection Application Programming Interface, better known as an API.

An application programming interface is a connection between computers or between computer programs. It is a type of software interface, offering a service to other pieces of software. A document or standard that describes how to build or use such a connection or interface is called an API specification (Wikipedia)

Here we can see under the hood of the API and see the lines of code which assist it to function. Through the prototype API, the CRAs are able to perform any of the following functions:

- Check mass & quality of e-waste at collection depots.

- Check mass & quality of e-waste within SMARC units.

- Check mass & quality of e-waste across collection depots and SMARC units.

- Trigger a collection of e-waste from depots.

- Set thresholds for automatic collection of e-waste from depots.

By providing CRAs with access to data about the e-waste network, SMARC ensure the e-waste can be recycled more responsibly, sustainably and safely.

Manufacturer Story

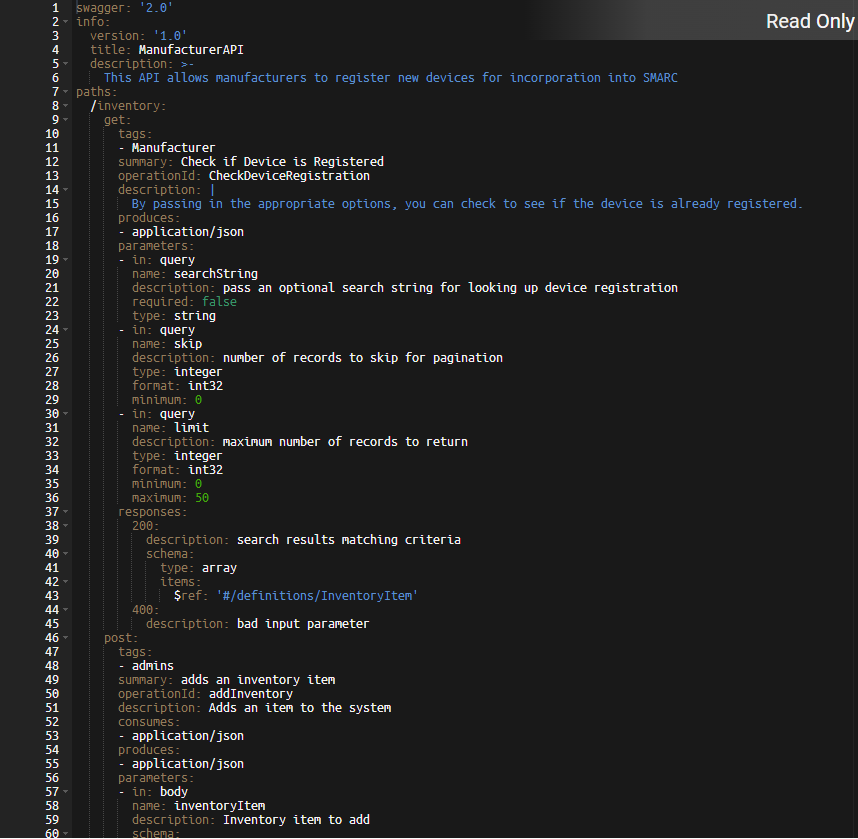

The Manufacturer aspect of the SMARC system is perhaps the most ambitious aspect of the prototype. Consistent with the systems based analysis we have adopted to develop the SMARC CPS, we have put forward a number of recommendations for reform to the role played by manufacturers in the e-waste system.

One of the key value propositions of SMARC is that it attempts to create a closed-loop or cradle to cradle design system for technology, such that after it has been processed as e-waste, the raw materials can be extracted and returned to the manufacturing process.

This depends on SMARC being able to track the resources coming into the e-waste system at the point of collection and this requires co-operation or regulatory obligations being imposed on technology manufacturers. Specifically, SMARC is proposing that manufacturers register any and all devices they manufacture or import into Australia into the SMARC system via our purpose-built manufacturer API.

This is a straightforward system for manufacturers to upload a selection of relevant data about their devices, including images to assist the machine learning model, and the chemical composition of the products.

Once the products are recycled and these elemental components are extracted. They can then be returned to the manufacturers, according to the fraction of their devices deposited via SMARC. The prospect of being able to extract elemental components, or essentially raw materials, from e-waste is not as far-fetched as it might seem. There is incredible work being done in recycling innovation by our friends Clean Earth Technology (working on technology to extract gold from motherboards without harsh solvents) and MicroFactories from the UNSW (working on amazing prototype factories that literally break technology into its constituent components. In case you were wondering, this literally means melting down a piece of e-waste and using precise heat control to separate out all the different metal components, as well as plastics and ceramics. If you haven’t we highly recommend you check out the innovations they are working on