What We Made

We built a cyber-physical system, which we have called ‘SMARC’, which stands for ‘Smart, Autonomous, Recycling Cradle’. SMARC is actually a broader systems intervention we have developed into the e-waste recycling system, and this physical product we have built is just one component of that intervention. It also includes purpose built APIs for our collection partners, our recycling partners and our manufacturing partners.

Hardware

To help explain what we made, let’s start with the physical build or hardware, which we’ll call the SMARC unit:

- The SMARC unit is effectively a smart e-waste recycling bin.

- Users take their items of e-waste and place them on the scanning tray, which has been handmade from wood.

- The user interacts with the SMARC unit by way of the touch-screen secured to the front, which is connected to Raspberry Pi inside the bin.

- The external built componentry is all secured to the unit by a handmade wooden frame, which was designed and built by Myrna specifically to fit this project. When the acrylic raspberry pi camera broke, Myrna made a new one entirely out of wood!

- Once placed on the tray, the Raspberry Pi camera detects the item and our machine learning algorithm identifies the type of e-waste and its condition.

- From the visual recognition input, our machine learning algorithm determine whether the item is recyclable or resellable and whether the user is entitled to any cash-back in exchange for the e-waste.

- The machine learning algorithm is based on a Teachable Machine dataset we created. For the purpose of the prototype, the dataset only includes a selection different mobile phone models. However, at scale the idea is that SMARC units would be able to recognise all e-waste items.

- The cash-back entitlement is determined by the value of the resources contained in the e-waste (if it is to be recycled) or the value of item if it was resold.

- At this point, the user can decide whether to accept the proposed payment or refuse.

- If the user’s e-waste item has been identified as being in a good enough condition for re-selling, they take a protective bubble wrapper from the back and secure it using a unique identifier QR code that will be printed out once the user confirm and finalise the process. This ensures that when the content of the SMARC unit is sorted, the recycling and reselling items can be easily separated.

- If they accept, the user then deposits the item into the SMARC unit, along with any other e-waste that requires recycling, by way of the automated deposit door on the top of the unit. For the purpose of the prototype, this has been made using a MicroServo, a circuit playground and a motion sensor detector.

Internal built components

- Extensive work also went into the build component inside the bin:

- There is a prototype lock system on the lid to secure the bin and ensure the security of people’s e-waste. This will need to refined further beyond the prototype.

- Internally, there is more bespoke woodwork by Myrna – a wooden box to protect the RPi and the PiCamera cable.

- Finally to add some wow factor and flair we have included light-up strips around the SMARC unit and a light sensor which is activated when the bin is opened, to ensure easy access to the contents. This design aspect was inspired by Myrna’s homework task from F4 – Moments of Partnership and the Mantis Shrimp’s unique sight abilities.

Software

- User Experience Marvel App

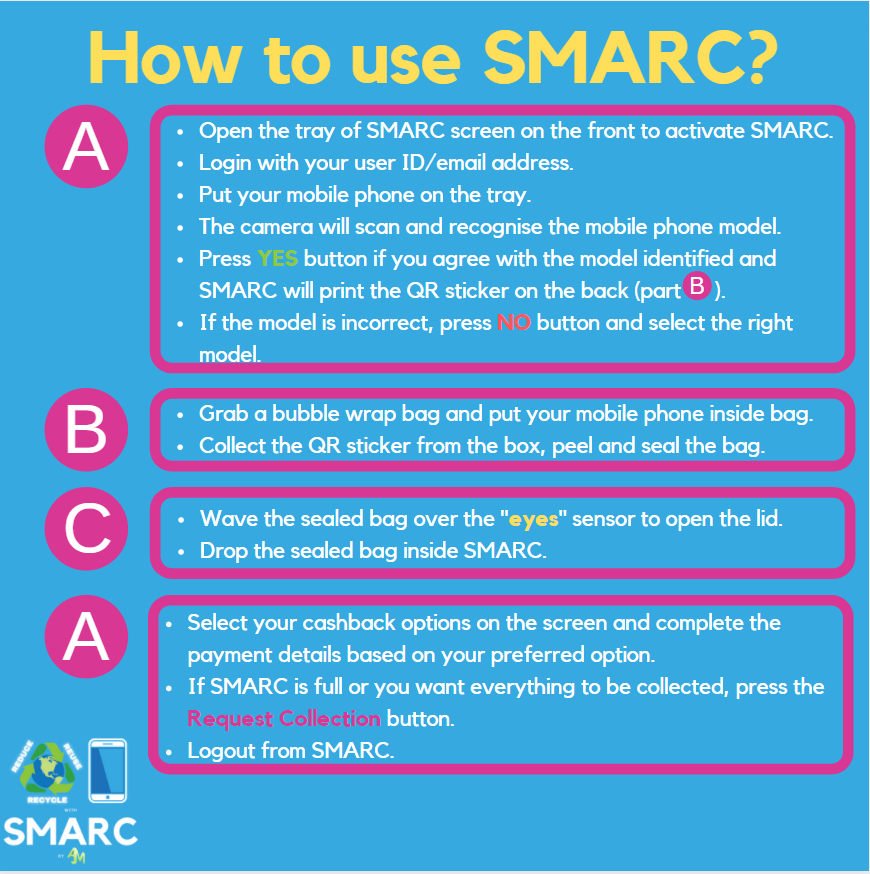

As part of the built component of SMARC, we have also considered the user-experience. Around the SMARC unit, you can see stickers of letter. These letter indicate the order with which the SMARC unit should be used and correspond with an easy to follow UX guide, to assist users that are having difficulty with the device. It walks users through an easy to follow, 4 step guide.

2. API 1: Manufacturer API

An API to allow manufacturers to upload required information to the SMARC network about products they were manufacturing or importing into Australia. Also provided a means of highlighting the need for regulatory reform to be introduced alongside the CPS intervention of SMARC.

3. API 2: Collection API

An API to allow recyclers to check on the e-waste available throughout the network of SMARC devices and depots. Also allowed recyclers to set thresholds for automatic collection events or to prompt a collection event manually. This is important means of demonstrating the role of API.

Purpose

SMARC’s purpose is to make e-waste recycling intuitive and easy, by bringing collection to the user and secondly enabling optimised and efficient e-waste collection. Through these two key value propositions, SMARC optimises the first and crucial stage in the e-waste recycling process – collection. At this point, SMARC’s use of smart sensors and IOT technology ensures the capture of previously unknown e-waste data and co-ordination of collection services. By making a cybernetic intervention at this point, SMARC makes a positive contribution to the downstream stages of the e-waste recycling system. As such, there is a higher order value proposition to SMARC: by optimising the collection system, the entire e-waste recycling system benefits, leading to improved environmental outcomes and recovery of valuable resources that are currently being lost to landfill.

Motivation

There are now more than 50 billion of mobile phones globally. Think about all the other tech we make, buy and bin. Most goes to landfill and we call it e-waste. Yet it contains valuable materials we can reuse. Including gold, platinum, aluminium, copper and rare earth elements. With our current approach to e-waste, we’re sending $10 billion dollars worth of resources to the tip each year. In Australia, tech manufacturers are required to fund free and accessible e-waste collection. So why isn’t it working? The reasons people don’t recycle their e-waste are actually pretty simple, 83% of people don’t know where to take their e-waste and 60% didn’t know it was possible as one of the TechCollect research highlighted below.

We are taken by the way Dr Crawford breaks down the often obfuscated issues surrounding the tech industry, supply-chains and our use of technology. Anatomy of an AI system (Amazon Alexa) succinctly highlights the labour and resources that go into building items of technology that we purchase and discard on a daily basis. Our group was inspired to try to put the message of this piece into action and encourage the community at large to address this pressing problem of e-waste and over-consumption.

/cdn.vox-cdn.com/uploads/chorus_image/image/61251349/Screen_Shot_2018_09_07_at_5.53.10_PM.0.png)

The UNSW Centre for Sustainable Materials Research and Technology (SMaRT@UNSW), led by Professor Veena Sahajwalla, is innovating with micro-factories. These small factories use state of the art technology to break down e-waste into its separate constituent components. The work of the Centre shows great vision for the potential to go beyond recycling and actually remake e-waste into raw materials. We’d like to see these micro-factories rolled out at scale and we are hopeful our CPS will be a key node in cradle to cradle use of e-waste materials.

We are motivated to create the critical infrastructure:

- To shift e-waste from people’s homes to recycling facilities.

- To recover the valuable resources contained in e-waste and repurpose them for new technologies.

- And to support the work Australia’s industry leaders in e-waste recycling, including: Clean Earth Technologies, Australia and New Zealand Recycling Program and the incredible micro-factories being developed at UNSW.

Applied cybernetics gives us the tools to design AI-enabled critical infrastructure to build an e-waste recycling system that actually works. And it all starts with the point of collection, using SMARC which is accessible at the household level and is part of the bigger e-waste ecosystem.

- In deciding on our project, we started by looking at the breadth of ideas that could be covered by CI.

- We soon realised that the definition of critical infrastructure is contested and can cover a myriad of things. We looked at such diverse topics as: natural water resources, managing redundant industrial infrastructure (like oil rigs) and smart water meters for domestic use.

- Ultimately, we took advice and focused on our values and problems we found interesting, rather than the technology itself.

- The more we got into researching issues related to critical infrastructure, none we encountered had any clear cut technological solution. They all demanded a systems of systems approach, where a technological intervention might assist but not resolve the matter.

- We eventually came to the problem of e-waste. Found overwhelming research on the environmental costs of e-waste, in terms of the initial environmental costs of its manufacturing (looked at this year through the work of Kate Crawford), what it leaches into the environment as toxic chemicals when it goes to landfill.

- E-waste is responsible for 70% of the toxic chemicals such as lead, cadmium and mercury found in landfill – and 23,000 tonnes of CO2 emissions would be saved if half of the televisions discarded annually were recycled

- This problem is not new but it is growing.

- 140,000+ tonnes of electronic waste generated by Australians every year

- Fewer than 1% of TVs and around 10% of PCs and laptops are recycled Australia wide

- Electronic rubbish is growing at three times the rate of any other waste stream

- Discarded devices are piling up around the world at a rate of 40 million per year

- 98% of the components in your computer or television can be fully recycled

- It seemed a really topical and relevant issue for the NBE to dive into. We started to reach out to people working in industry. We spoke to:

ANZRP CEO

CET Chief Technical Officer

- Each was involved at different stages of the e-waste recycling program and was also at different stages in terms of the scale of their operations.

- The overwhelming message was that one of the biggest challenges right now with e-waste was collection. Presently there are just a series of disparate e-waste deposit points for people to take their e-waste. It is confusing, leads to poor quality (items that are not e-waste recyclable being deposited) and makes the downstream recycling processes much more difficult.

- In the collection niche of the e-waste recycling system, we started to see a good use-case for a CPS. In fact, we started to sketch out the first iteration of the idea on our call with CEO Warren Overton, who loved the idea of e-waste collection as a service that goes to the consumer (rather than the consumer having to come to it) and as a means of obtaining data on e-waste being deposited into the network and the time of depositing. He noted this would make the processing and sorting stages much easier.

- At scale, these individual SMARC units become data points of e-waste throughout a city. The data helps co-ordinate collection and other logistics throughout the e-waste cycle. Further, the data contributes to more efficient recycling and reselling of devices that are still functional. The idea of creating a dataset for e-waste, also opens up a conversation of the role of manufacturers in ensuring the recyclability of their products and contributing data to the network – namely, the chemical composition of their products which is invaluable for recycling purposes. This helps develop policies directed towards cradle to cradle design.

- In developing the SMARC idea we took a little bit longer than we would have liked. But we were committed to building something with real world application, that was scalable and could demonstrate the potential of CPS. Through SMARC, we’ve found a way to grapple and ultimately start to realise some of those ambitions.

- NBE we are really interested in the problem of scale. Why does interesting tech not make it into daily use? How could we take a simple idea/intervention and see how it could be progressively scaled up to make a significant impact at scale. I think we found that in SMARC – it’s a relatively simple CPS concept, using technology accessible to us, but the more we played with it and imagined it bigger and bigger, the more opportunities it presented for significant impact.